From semiconductor to gemstone and metal/bricks cutting, we have several types of diamond saw blades. Our finest blades are available in different configurations and are sure to deliver the best performance. It’s because of the bond that different diamond blades are used for cutting hard and soft materials. If you use good quality diamond saw blades, you can easily cut porcelain, glass, concrete and tile even in dry conditions.To select the best diamond blade for cutting porcelain tiles, you should look at following things:

Type of Blade

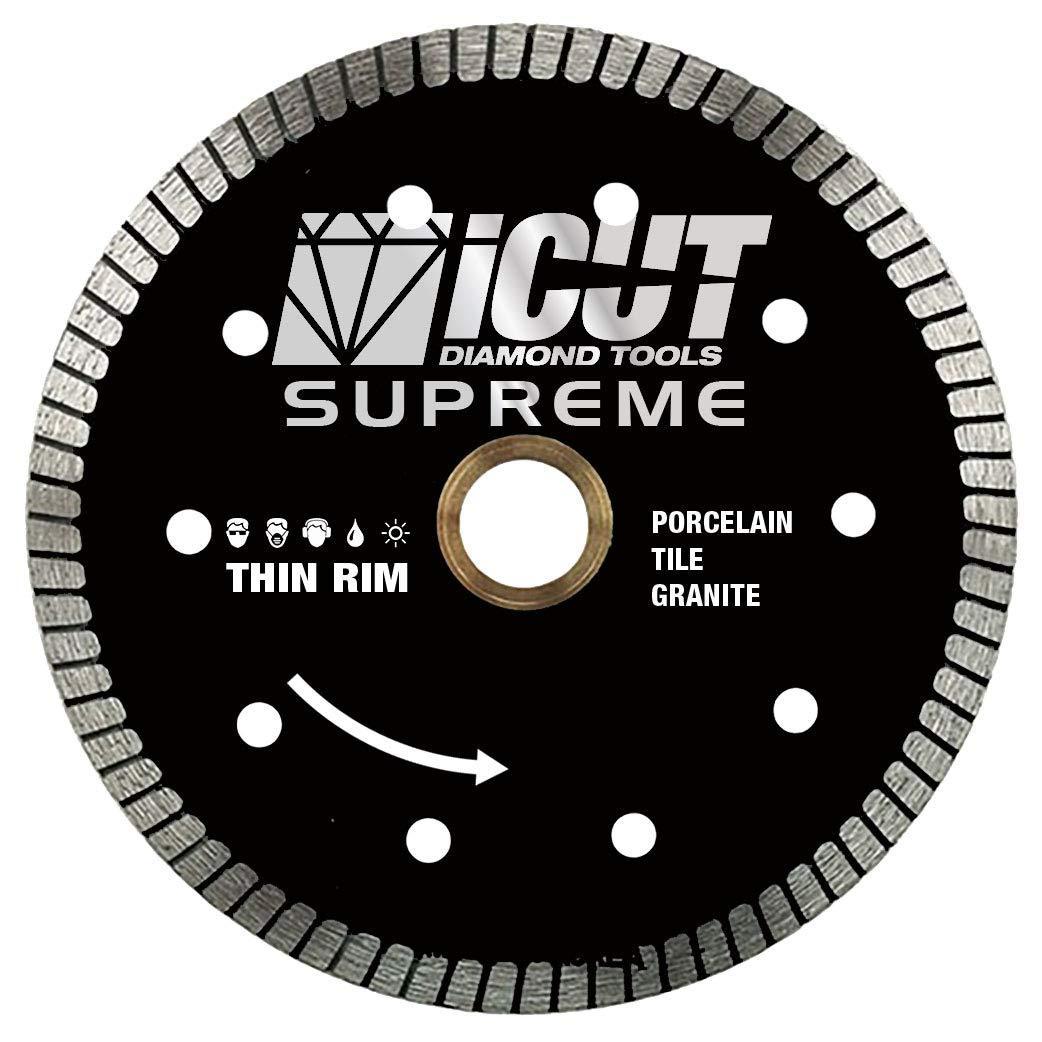

To cut porcelain tiles with very much accuracy, you need to have a carved blade having an angle grinder with it. Out of all, ceramic turbo mesh diamond blades are considered as the best blades for cutting porcelain tiles. Most of these turbo diamond blades have an expected cutting life of 2 hours.

Performance

All types of worker will rate diamond saw blades in a different way. One professional will suggest a particular diamond blade for porcelain tiles because of its speed. While other will say his diamond saw blade is best because of its low cost. Last, there are also some individuals who will choose the perfect blade by looking at the dirt created from it. Therefore, you can purchase the specific diamond blade that can deliver high performance.

Continuous Rim

When you work with conventional blades, sometimes it happens that material is chipped so easily because of hard porcelain material. Also, in some cases heat is also generated because of the friction created while cutting. One way to stop all these is to use a ceramic porcelain blade that has a continuous rim. This helps in decreasing the overall gap, thereby reducing the overall wastage of the material.

Strength

The bond is also an important part of the blade. The composition of the aggregate defines the overall strength of the blade. Therefore, we need to use thin rim continuous blades for cutting porcelain tiles. The blades with continuous rim also help in reducing the wastage of overall material. Thus, edges of the stone are not beaten up and we are able to achieve a smooth cutting experience.

Conditions

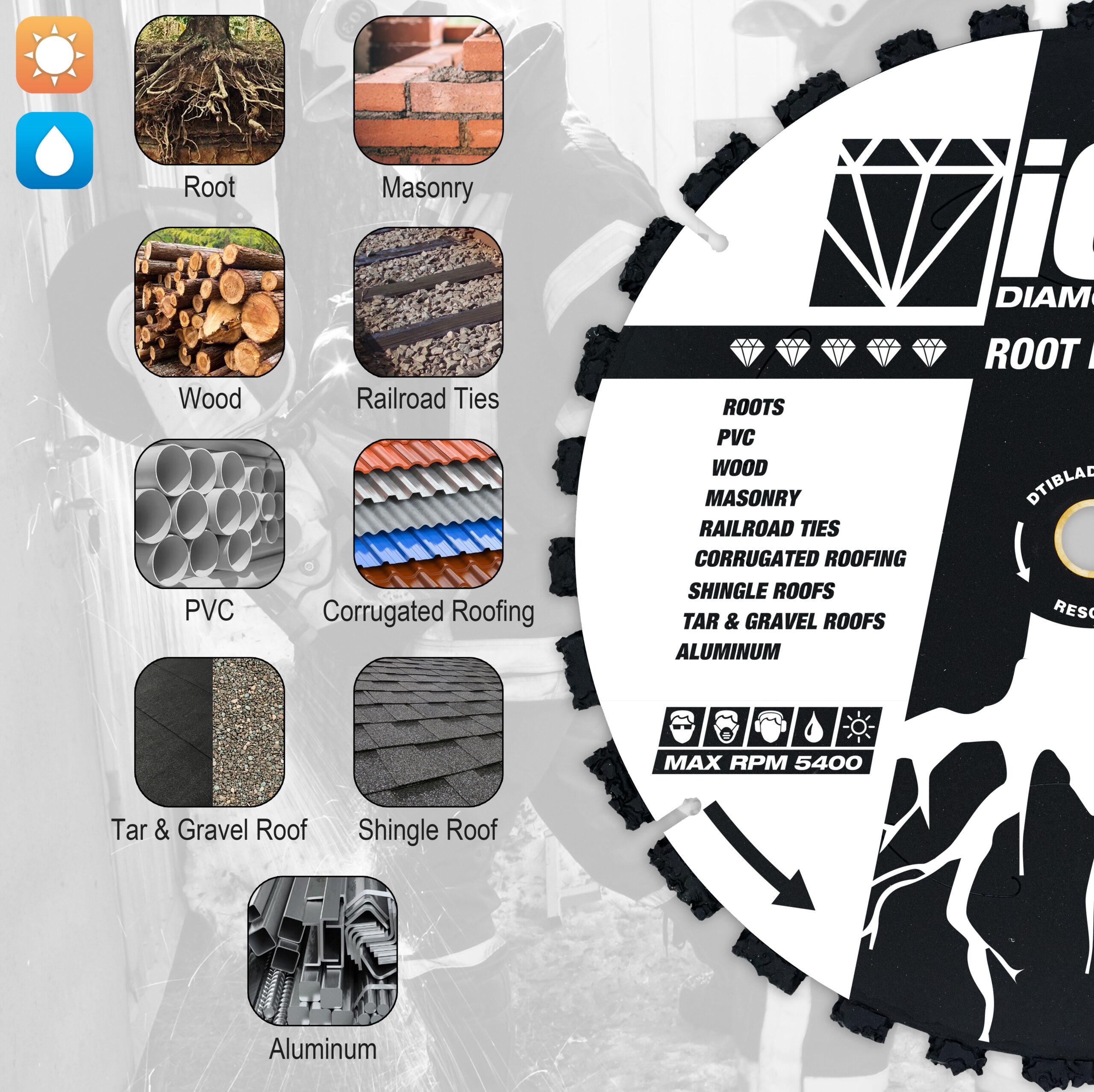

Do you know that water can increase the overall lifespan of a diamond blade? With wet blades, there are lesser chances of overheating generated from friction. Abrasive materials like Borazon, Corundum etc work best with diamond blades in these conditons. However, there are also some cases where we need dry cutting. Therefore, you need to select the specific diamond saw cutting blades for your construction work.

Wrapping Up

In order to avail the best cutting experience with porcelain tiles, you must select the right saw diamond blades. The accurate shaped diamond blade helps in preventing unwanted cuts and extra wastage. To avoid overheating, you should use a diamond blade with a continuous rim. If you use diamond saw blades developed from stainless steel, you can enjoy very high performance for longer periods. Use the turbo shaped diamond blades to easily cut asphalt, ceramic, bricks, porcelain tiles etc.